- Home

-

About

The company currently has one national encouraged energy-saving and environmentally friendly vertical grinding machine production line, with an annual design production capacity of 2 million tons, strong technical strength, and complete equipment support.

The company currently has one national encouraged energy-saving and environmentally friendly vertical grinding machine production line, with an annual design production capacity of 2 million tons, strong technical strength, and complete equipment support. -

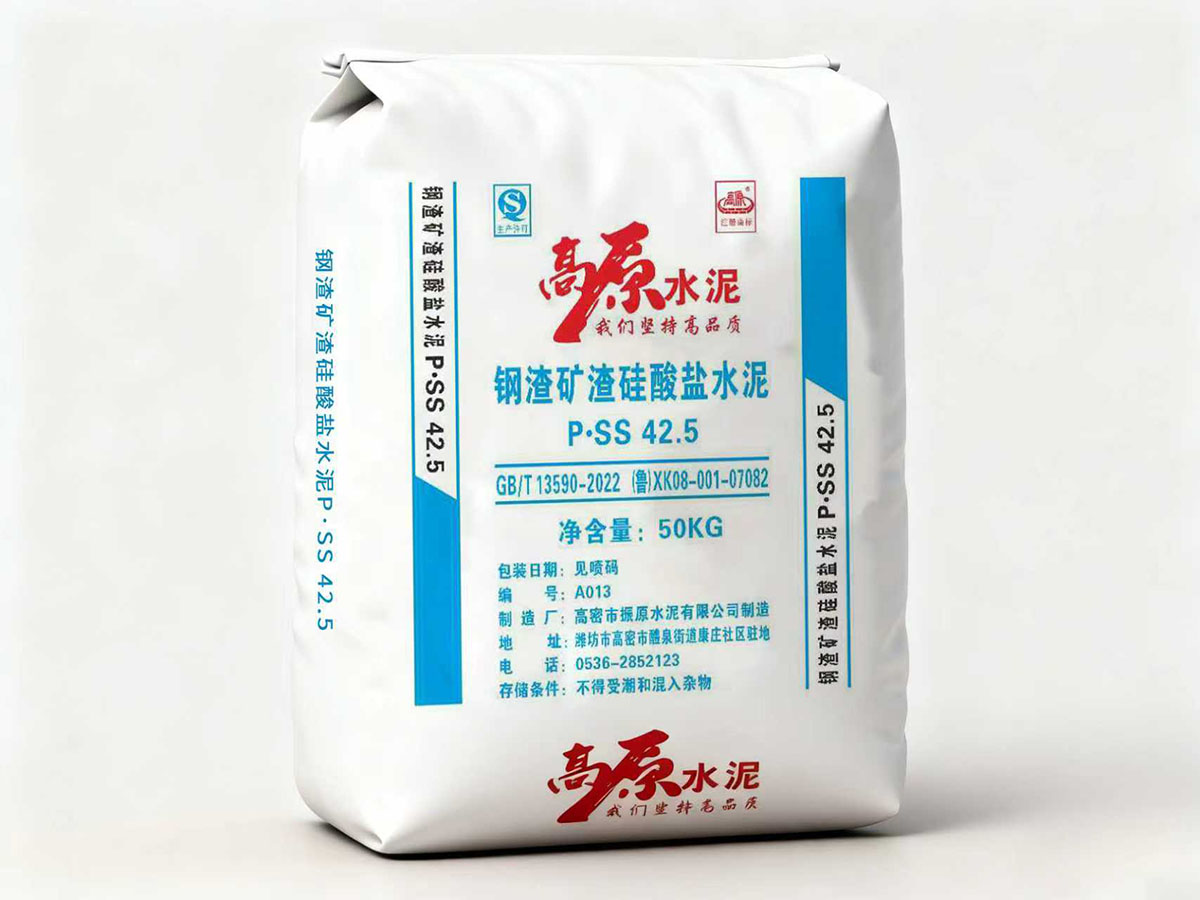

Product

The company obtained the "Shandong Province Industrial Standard Product Approval Certificate" in 2021 and was approved by the Shandong Provincial Quality and Technical Supervision Bureau in October of the same year

The company obtained the "Shandong Province Industrial Standard Product Approval Certificate" in 2021 and was approved by the Shandong Provincial Quality and Technical Supervision Bureau in October of the same year -

Solution

54 years of technological accumulation, breaking through barriers and standing firm | Helping cement grinding enterprises break free from the "red ocean of internal competition" and achieve cost reduction and efficiency improvement

54 years of technological accumulation, breaking through barriers and standing firm | Helping cement grinding enterprises break free from the "red ocean of internal competition" and achieve cost reduction and efficiency improvement - Partner

- Contact